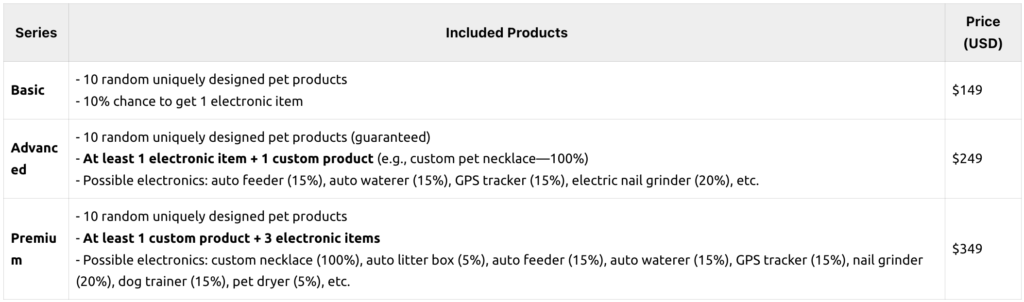

Feeling frustrated with pet suppliers who promise quality but deliver disappointment? You're not alone. Many retailers fall into the trap of prioritizing price over partnerships, only to watch their reputation crumble when products fail to perform.

The most successful pet retailers prioritize suppliers offering unique designs, flexible ordering options, strict quality control processes, and reliable production schedules over those simply offering the lowest price. This approach leads to higher customer satisfaction, repeat business, and ultimately better profit margins.

When I entered the pet industry years ago, I quickly realized that product sourcing decisions could make or break a retail business. Let me share insights that will help you avoid costly mistakes and build a thriving pet product business.

How Do You Find Pet Product Suppliers That Won't Disappoint Your Customers?

Every retailer has experienced that sinking feeling when opening a shipment only to find products that look nothing like the samples. Your customers trust you to provide safe, quality products for their beloved pets.

The key to finding reliable pet product suppliers is looking beyond price comparisons and examining their design capabilities, material sourcing practices, quality control systems, and production capacity. Request detailed information about their manufacturing processes, material safety testing, and ask for references from their existing customers.

I've visited hundreds of pet product factories throughout China, and I've noticed a disturbing trend: many factories produce virtually identical products, creating intense price competition that inevitably leads to corner-cutting on materials and craftsmanship.

The factories truly worth partnering with stand out by dedicating significant resources to product innovation. Over 30% of our staff focuses exclusively on research and development, designing unique products that help our retail partners differentiate themselves in crowded marketplaces.

When evaluating potential suppliers, ask these critical questions:

- Can they show you their design process and recent innovations?

- What percentage of their products are proprietary designs versus generic items?

- Do they have transparent material sourcing and testing protocols?

- Can they provide certifications for product safety?

- Will they allow you to inspect their production facilities?

Why Is Product Quality So Difficult To Verify When Sourcing Pet Products?

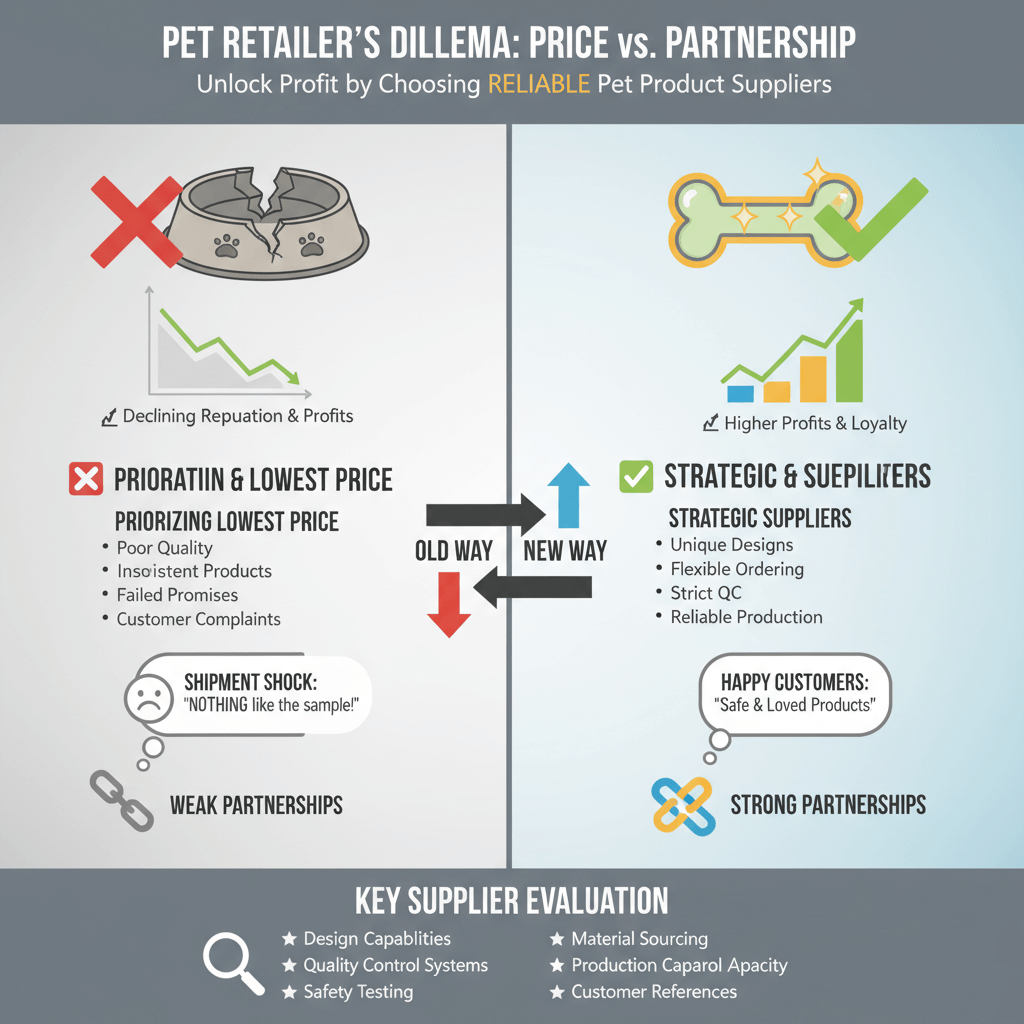

Many retailers have been burned by beautiful product photos that don't match the disappointing reality that arrives in their warehouse.

To accurately verify pet product quality, request comprehensive material safety reports, production samples, and detailed manufacturing specifications. Leading suppliers will provide documentation about material sources, production processes, and conduct video calls showing actual production rather than just sending photoshopped marketing images.

The disconnect between product images and reality stems from two problems: some suppliers deliberately use misleading images, while others simply lack consistent quality control processes that ensure every product matches their best samples.

Our approach differs significantly. We implement a rigorous quality verification system:

- Raw Material Verification: Every incoming material is tested and scored against safety and durability standards

- Production Monitoring: Quality checks occur at multiple stages during manufacturing

- Pre-Shipment Inspection: Full documentation with photos and videos before shipping

- Third-Party Verification: Optional independent testing for retailers requiring additional certification

This level of transparency builds trust and prevents costly product failures that damage your brand reputation with customers.

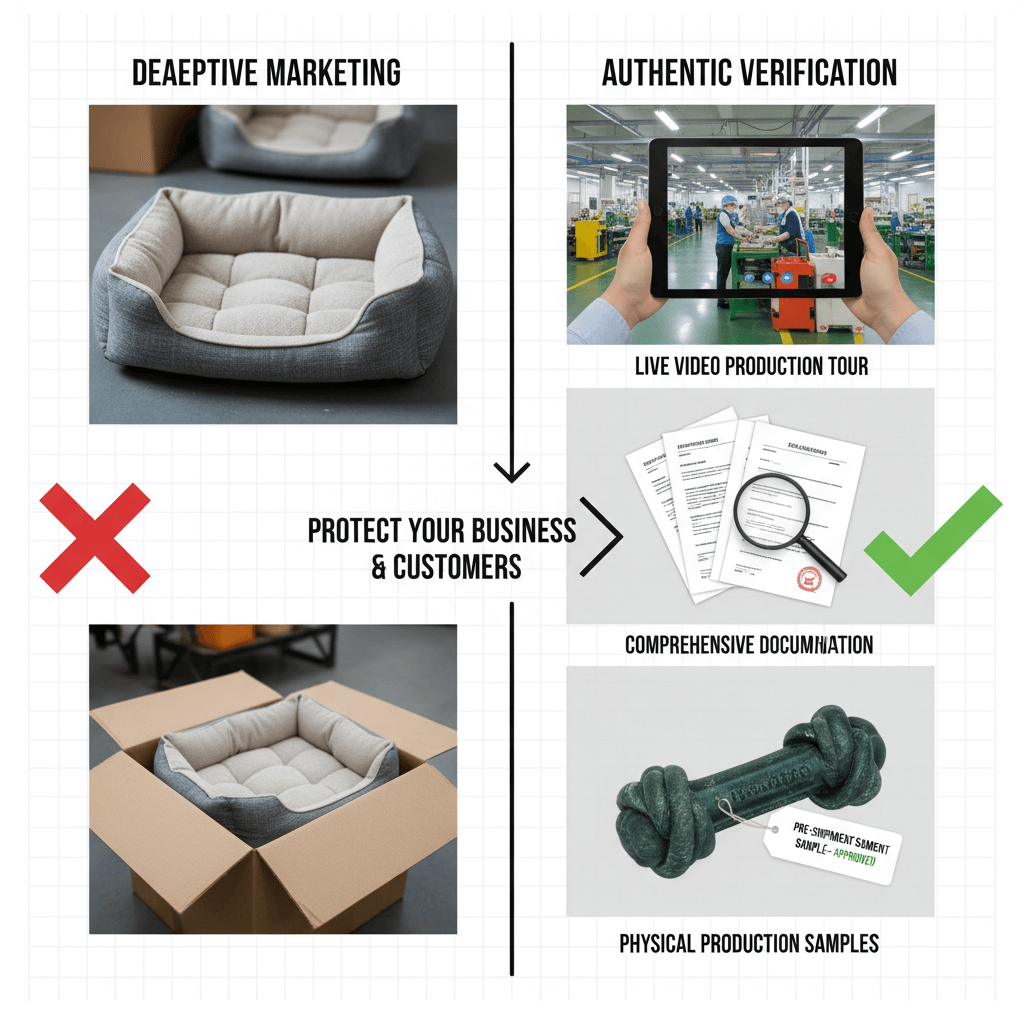

Are High Minimum Order Quantities (MOQs) Preventing Your Business Growth?

For smaller retailers and those testing new product lines, traditional MOQs of 1000+ units per style create excessive inventory risk.

While industry-standard MOQs for pet products typically range from 500-1000 pieces per item, forward-thinking suppliers now offer flexible options starting at 200-400 pieces per SKU with mixed color options. This approach significantly reduces inventory risk while allowing retailers to test market reaction before committing to larger orders.

I understand the challenges small retailers face when entering the pet product market. While large factories optimize for production efficiency with high MOQs, this creates significant barriers for businesses still building their customer base.

That's why we've restructured our production systems to accommodate mixed-batch orders that would be unprofitable for most manufacturers. For new partners, we offer trial orders as low as one carton (approximately 200-400 units depending on the product) with mixed color options.

This approach creates more complexity in our production scheduling and increases inventory management challenges for us, but it builds stronger partnerships by allowing our retail partners to:

- Test multiple product varieties with minimal risk

- Adjust inventory based on actual sales data

- Preserve capital for marketing and business growth

- Scale order volumes as their business expands

Can Your Pet Product Supplier Handle Holiday Season Demands?

Nothing destroys retailer profits faster than missed deliveries during peak selling seasons like Christmas or summer vacation periods.

Production stability is essential for retail success, particularly during holiday seasons when demand spikes. Verify supplier production capacity (number of lines), backup manufacturing arrangements, holiday scheduling protocols, and delay compensation terms before committing to seasonal inventory plans.

Many smaller factories in China experience significant disruptions during Chinese New Year and other holidays, creating delivery delays precisely when you need products most. Additionally, their limited production capacity means they quickly become overwhelmed during peak global ordering seasons.

Our manufacturing network includes 32 production lines across multiple facilities in Shenzhen (smart electronic pet products), Yiwu (conventional pet accessories), Hefei (pet food production), and specialized facilities for cat litter and other specialized products. This distributed manufacturing approach ensures:

- Year-round production capability with minimal holiday disruptions

- Capacity to handle surge orders during peak demand periods

- Backup production options if any single facility faces challenges

- Consistent on-time delivery even during Chinese holiday periods

For retailers planning seasonal inventory, our production scheduling team creates detailed timelines that account for material procurement, manufacturing time, quality control, and shipping duration to ensure your products arrive before your selling season begins.

How Important Is Supplier Communication When Importing Pet Products?

Communication breakdowns lead to misunderstandings about specifications, delivery dates, and quality expectations, especially when working across language barriers and time zones.

Effective communication is crucial when sourcing pet products internationally. Look for suppliers with dedicated account teams who speak your language fluently, use modern communication tools, provide regular production updates with photos/videos, and maintain consistent response times regardless of time zone differences.

I've seen countless retailer-supplier relationships deteriorate due to communication failures. Missed emails, misunderstood specifications, and unclear expectations create frustration and costly mistakes.

We've solved this challenge by creating specialized communication teams for different global regions. Our seven international support teams ensure:

- Communications in your preferred language and time zone

- Regular updates throughout the production process

- Video calls that allow you to virtually inspect production

- 24-hour response policy for all inquiries

- Comprehensive documentation of all agreements and specifications

This communication infrastructure costs more to maintain than the typical factory approach, but dramatically reduces costly errors and builds stronger partnerships.

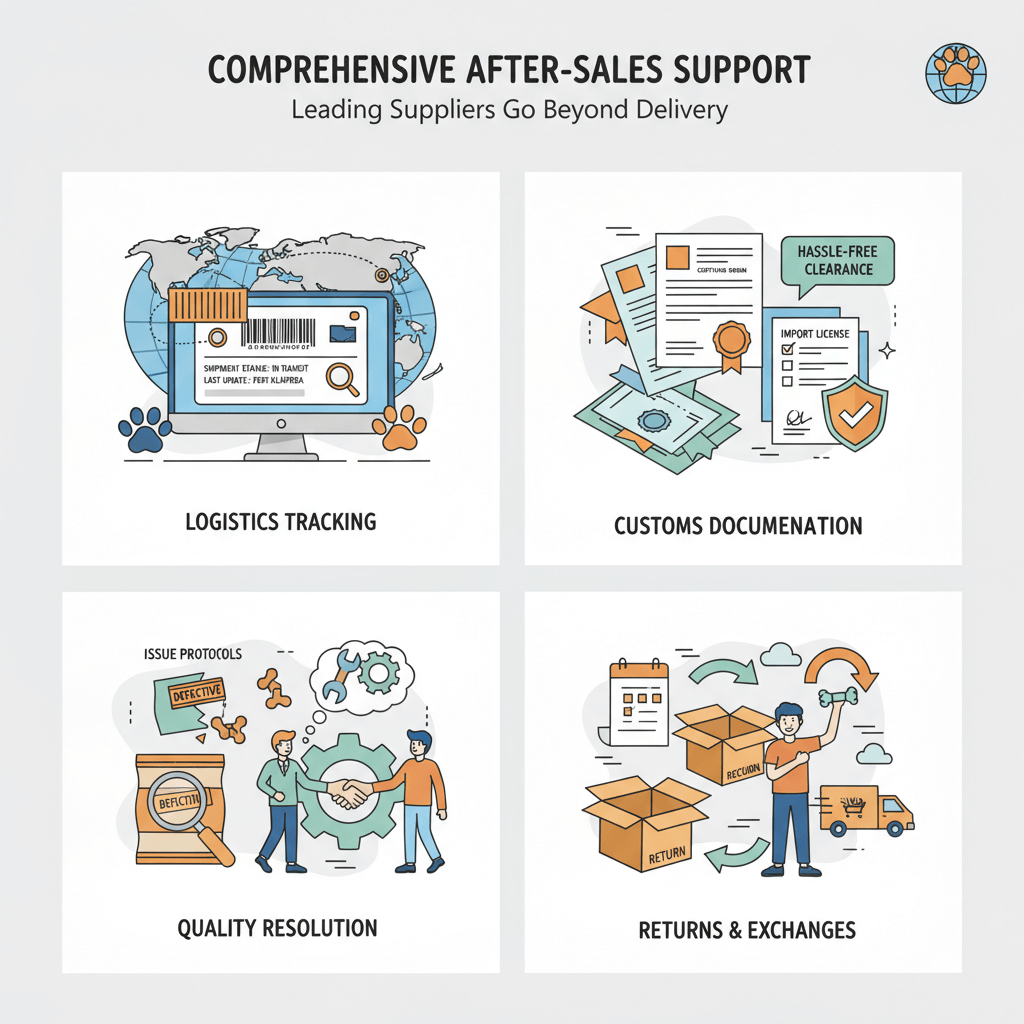

What Support Should You Expect After Receiving Your Pet Product Order?

Many manufacturers consider their responsibility complete once products leave their facility, leaving retailers to handle any subsequent issues alone.

Comprehensive after-sales support is essential when importing pet products. Leading suppliers provide logistics tracking assistance, help with customs documentation, resolution protocols for quality issues, and systems for managing product returns or exchanges when necessary.

The journey from factory to your store involves numerous potential complications including shipping delays, customs challenges, and occasional quality issues. Working with suppliers who remain engaged throughout this process significantly reduces your risk.

Our after-sales support system includes:

- Production tracking and reporting

- Quality verification documentation

- Pre-shipment packaging photography and videos

- Logistics monitoring and intervention when needed

- Support with customs documentation and compliance

- Resolution processes for any quality concerns

- On-site visits for major partnerships

We've found that this comprehensive support system builds long-term relationships with retailers who value reliability over marginally lower prices.

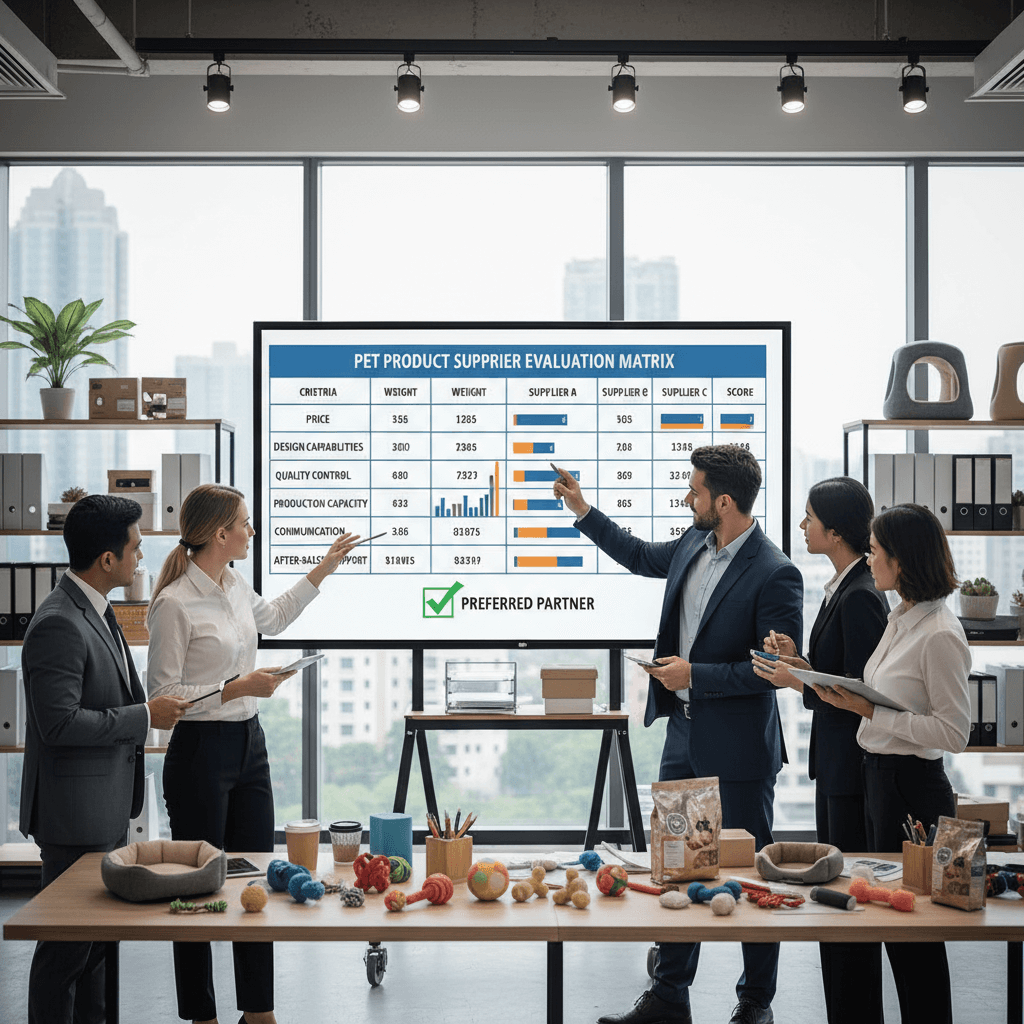

How To Make The Right Choice Between Competing Pet Product Suppliers?

With thousands of pet product manufacturers available, how do you identify those worth partnering with?

When comparing pet product suppliers, look beyond initial price quotes to evaluate their design capabilities, quality control processes, production capacity, communication systems, and after-sales support. Create a comprehensive evaluation matrix that weights these factors based on your specific business needs rather than making decisions on price alone.

The most expensive mistake retailers make is selecting suppliers based primarily on quoted prices. This approach fails to account for hidden costs that emerge later: quality problems, delivery delays, communication challenges, and products that fail to excite customers.

I recommend creating a supplier evaluation framework that considers:

- Product Differentiation: Can they provide unique designs that set your business apart?

- Quality Consistency: What systems ensure every product matches the approved samples?

- Price Stability: Will they engage in "bait and switch" pricing after initial orders?

- Production Reliability: Can they consistently meet delivery timelines?

- Communication Clarity: How effectively do they respond to questions and concerns?

- Problem Resolution: What happens when issues inevitably arise?

Each of these factors contributes significantly to your true cost of goods and ultimately determines whether your pet product business thrives or struggles.

Conclusion

Choosing the right pet product supplier creates the foundation for retail success. While initial price comparisons are important, the most successful retailers prioritize partnerships with manufacturers offering unique designs, quality consistency, production reliability, and comprehensive support.

At Petmmbear, we specialize in designing and manufacturing distinctive pet products across 32 production lines in multiple Chinese facilities. With a 97% customer satisfaction rate, we provide complete sourcing solutions from initial consultation through design, production, shipping and after-sales support. Contact us through www.petmmbear.com to discover how we can help grow your pet product business!