China Private Label Pet Food Manufacturer

MOQ:1 ton

High Repurchase Rate:93.7%

International Standard Certificates

Package

Safe And High Quality Ingredients

All Certificates You Need

Exported to 50+ countries worldwide,ISO、HACCP、GMP etc

National Authority Certification

China's pet food export registration certificate, only about 20 factory have it in China

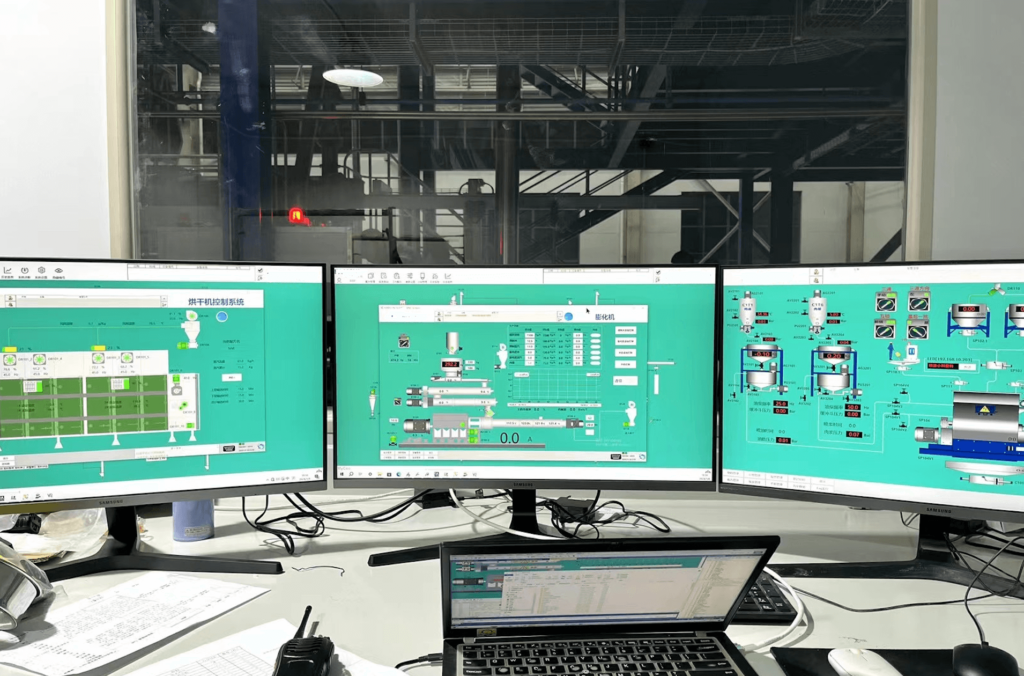

Factory Insights

Fast Production

32 Production Lines,Never Late for Orders

1-10 Tons,around 5 days

11-19 Tons,around 10 days

More than 20 Tons,around 20 days

Quality Control & Production Process

Sorting Incoming Materials

All raw materials (e.g. meat meal, grains, vegetables, vitamin-mineral premixes, etc.) are inspected for appearance, counted, and information verified at the time of acceptance.

According to the type of raw material and the supplier, a barcode system is used to record the batch information to ensure traceability

Raw Material Quality Control

The items tested in the laboratory for each batch of raw materials include, but are not limited to:

physical and chemical indicators (e.g., moisture, protein, fat content), microbiological indicators (e.g., total colony count, salmonella, E. coli), heavy metals, mycotoxins, and sensory characteristics (odor, color).

Classification of Raw Materials

Based on the results of quality control, raw materials are categorized as qualified and unqualified.

Qualified raw materials enter the production inventory; unqualified raw materials are labeled and returned to the supplier and entered into the raw material supplier end of year evaluation system.

Update inventory records to ensure that only qualified raw materials are used in production.

Processing & production

Production is carried out in strict accordance with approved recipes and processes.

This includes precise proportioning of raw materials, mixing, high-temperature puffing/cooking, drying, cooling, spraying of flavors/oils, molding, and internal/external packaging.

Real-time monitoring and recording of key parameters (e.g. temperature, pressure, time) are implemented throughout the production process to ensure process stability and product uniformity.

Finished Food Quality Control

Random samples of finished products are taken from the production line to test nutritional balance, particle size and taste.

Microbiological and chemical residue tests are conducted to ensure compliance with international standards.

Unqualified products are segregated and reprocessed, and qualified products enter the packaging process.

Pre-Shipment Final Inspection

Before the finished products are ready to be shipped out for shipment, the quality control personnel will carry out final inspection of the batch to be shipped.

Check whether the product name, specification, packaging, marking and quantity are accurate.

Check whether the outer packaging is intact and clean, and review the quality inspection report of the finished products of the batch to ensure that they meet the requirements of the customer order and the export standards before they are released for shipment.

Why Choose Us?

Quality

Safety inspection of incoming raw materials, one inspection during production and two inspections before shipment.

Delivery

With more than 10 years of established freight agent,offer you the best shipping ways with best price.

Production

Supported by 32 production lines, normal orders are completed in about 5 to 25 days.You don't need to worry about running out of stock on holidays anymore.

Profit

Strong purchasing power for materials to save more profit

Success Stories with Global Brands

Buyer Request:Same ingredients as Pedixxx & Royax Caxxx

In 2022, we received an inquiry from a European brand owner who wanted to customize a dog food and packaging for their own brand. Within a week, the customer visited our factory, and we provided all the relevant dog food of international brands on the market, and analyzed the products of the customer’s competitors, and finally made the blend through the formula ratio on the instruction manual. 10 days later, the customer passed the test of three samples. In the first year, the brand helped the client to increase sales in the dog food category by 37%, and the same year’s orders were not delayed once to affect sales.

In the second year, we developed new products according to the situation of competitors in the customer’s market and cooperated with the customer to do the corresponding marketing, and soon the sales figures increased to 55%.

Global Wholesale Partner

From Buyer

Satisfaction Rate

Testimonials

FAQ

MOQ for food it is 1 ton.

You need to send us the type of food(cats or dogs,wet or dry,and most importantly,% of protein and fat)then we could figure out the price for you or we can not provide the final price

We offer Dry & Wet food,snacks,supplements etc.

We also offer different functional customized food solutions for different types of pets as follows:

Joints/Gastrointestinal/Skin/Aged/Breeds etc.

We strictly enforce international food safety standards and monitor the entire production process. All raw materials are strictly screened and inspected, and our factory has passed ISO 9001 quality management system certification and HACCP,AAFCO,FAD food safety management system certification. In addition, we can provide third-party inspection reports to ensure that the quality of our products meets your requirements.

Ps:China's pet food export registration certificate, only about 20 factory have it in China

Of course! We have extensive experience in international trade and are familiar with the import requirements of different countries and regions. We can assist in obtaining export licenses, providing the necessary certification documents, and coordinating logistics and transportation to ensure that your goods reach their destination smoothly.

We source raw materials from globally recognized suppliers to ensure compliance with stringent quality standards. All raw materials are tested for safety and nutritional content before use. Please feel free to contact us for detailed information on the origin of our raw materials.

1. Trigger the factory's emergency plan and start the investigation and processing

2. Recall and evaluate the problematic products

3.10x compensation for the problem products (no quality problems yet)

Tips:The reason your order is delayed: Most small Chinese factories need to wait for more orders to be produced together to save costs causing delays.

We have a proven order management as well as production process where orders do not have to wait in line.

Production time for regular orders is as fast as 5-10 days, and the basic time for ocean freight is around 20 days.

Helped 150+ clients build their brands

Say”No”to Low Quality & Price food.

If you need a long-term stable supplier, please contact us!